Waste energy Solution Summary

One ton (2,000 pounds) of moisture-laden, unsorted MSW (garbage) produces 1.5MW when converted through Green Frog Power systems

Combined systems meet 2050 European Union standards for airborne emissions – today.

How Does 1 Ton of MSW = 1.5MW Net?

GFS doesn't use syngas to perpetuate conversion of waste like torch-based gasification systems = more net electricity sent to the grid

GFS uses 75% less electricity vs. other arc-gasifier systems = more net electricity sent to the grid

GFS uses both the heat & BTUs of the syngas to convert to steam/electricity – no need for syngas to be cooled/cleaned prior to combustion = more net electricity sent to the grid

GFS steam-to-condensate process maximizes conversion of heat to electricity = more net electricity sent to the grid

Leading Edge Technology

Compared to earlier plasma-arc decomposition processes, Green Frog Power’s system uses only one-fourth the energy to affect virtually total

decomposition of carbonaceous materials.

Leading Edge Technology

| Incineration | Plasma Torch | GFS | |

|---|---|---|---|

| Net MW per ton | .5MW | 1MW | 1.5MW |

| Waste Reduction | 65% | 83% | 100%* |

| Waste Type | MSW | MSW, Medical, Hazardous | MSW, Medical, Hazardous, Sewage |

| Moisture | Problematic | Problematic | 50%+ preferred |

| Process Temperature | 2,500oF | 4,500oF | 21,000oF–36,000oF |

| Dioxins, toxins and Furans remaining | Yes | Yes | No |

| Additional Air Pollution Controls | Yes(expensive bag houses) | Yes(lime-based scrubbing required) | No(meets 2050 European standards) |

*100% waste reduction is because the inert fly ash and metal slag can be recycled and/or sold.

Materials Processed at Naples Facility

Municipal Solid Waste

Sewage Sludge

Leachate Water

Petroleum Coke

Rubber Tires

Auto fluff

Acceptable Feedstock Materials

- Municipal Solid Waste

- Coal

- Agricultural Waste

- Rice Straw

- Paper Mill Sludge

- Sewage Sludge

- Auto Fluff

- Rubber Tires

- Petroleum Coke

- PCBs

- Medical Waste

- Wood Waste

- Refuse Derived Fuel

- Hazardous Waste

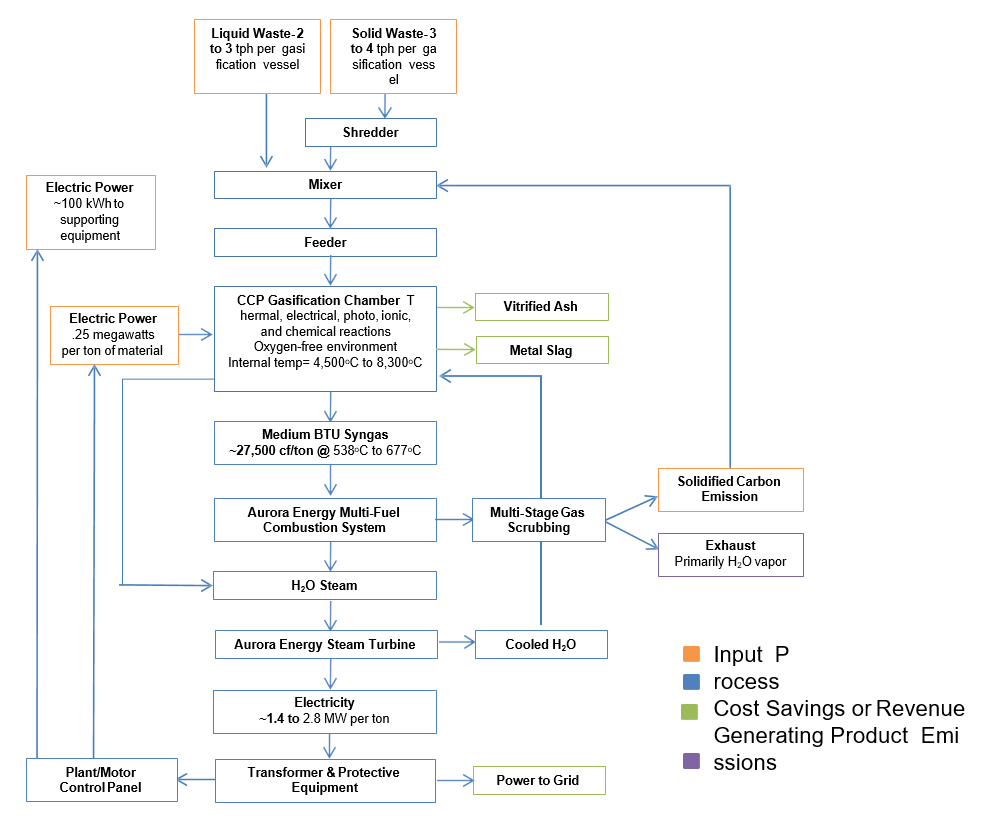

GFS Gasification System Overview

Next-gen GFS Gasification System being fabricated in Spokane Valley, Wash., USA (pictured left)

Material processed at rate of 3 to 5 tons per hour

Waste passes through photon-induced plasma arc field in center of chamber

Thermal, chemical, photo and ionic reactions break down and separate waste material at molecular level

Inert material cooled and conveyed through bottom, while syngas exits through top

GFS Technology Differentiators

Accepts nonhomogeneous material separate or mixed together MSW, sewage sludge, biomass, tires, computer waste etc.

Moisture content of feedstock is desirable Integration of leachate water or sewage sludge

Decontamination & vitrification of soils and other inerts

Virtually free of airborne emissions -- already meets rigid 2050 European Union environmental standards

Small system footprint -- modular construction and use of existing infrastructure with linear-scaling capacity

Instrumentation & controls allow for millisecond adjustments throughout plant for increased efficiency

Process Flow